Product Development, Mechanical Design & prototyping

303-927-8626

303-927-8626

Yitz Finch, Ph.D. is a mechanical engineer/SolidWorks/CNC machinist/maker/builder/teacher/mentor junkie looking for problems to solve. For the last 6 years, he has been designing and building experimental hardware supporting the research at the Colorado School of Mines.

He has designed and machined parts for research in astrophysics, nucl

Yitz Finch, Ph.D. is a mechanical engineer/SolidWorks/CNC machinist/maker/builder/teacher/mentor junkie looking for problems to solve. For the last 6 years, he has been designing and building experimental hardware supporting the research at the Colorado School of Mines.

He has designed and machined parts for research in astrophysics, nuclear physics, chemistry (microfluidics), battery chemistry, explosives, rock mechanics, combustion and more. But it's not just about cranking out parts. He often collaborates closely with research faculty and his know-how solves problems, moving the research forward.

Even before there's a sketch, there's a need. Together, we can execute a structured design process to ensure we deliver a product that meets your, or your customer's, needs. Nothing cute or fancy, just solid product development tools and methods.

When it's time for physical prototypes or tests, we make parts. But it's more than just a drawing handoff. We will talk with you about your parts, incessantly. Keeping manufacturing in house enables us to flow customer needs all the way down to part features. This ensures proper fit and function without parts leaving our shop.

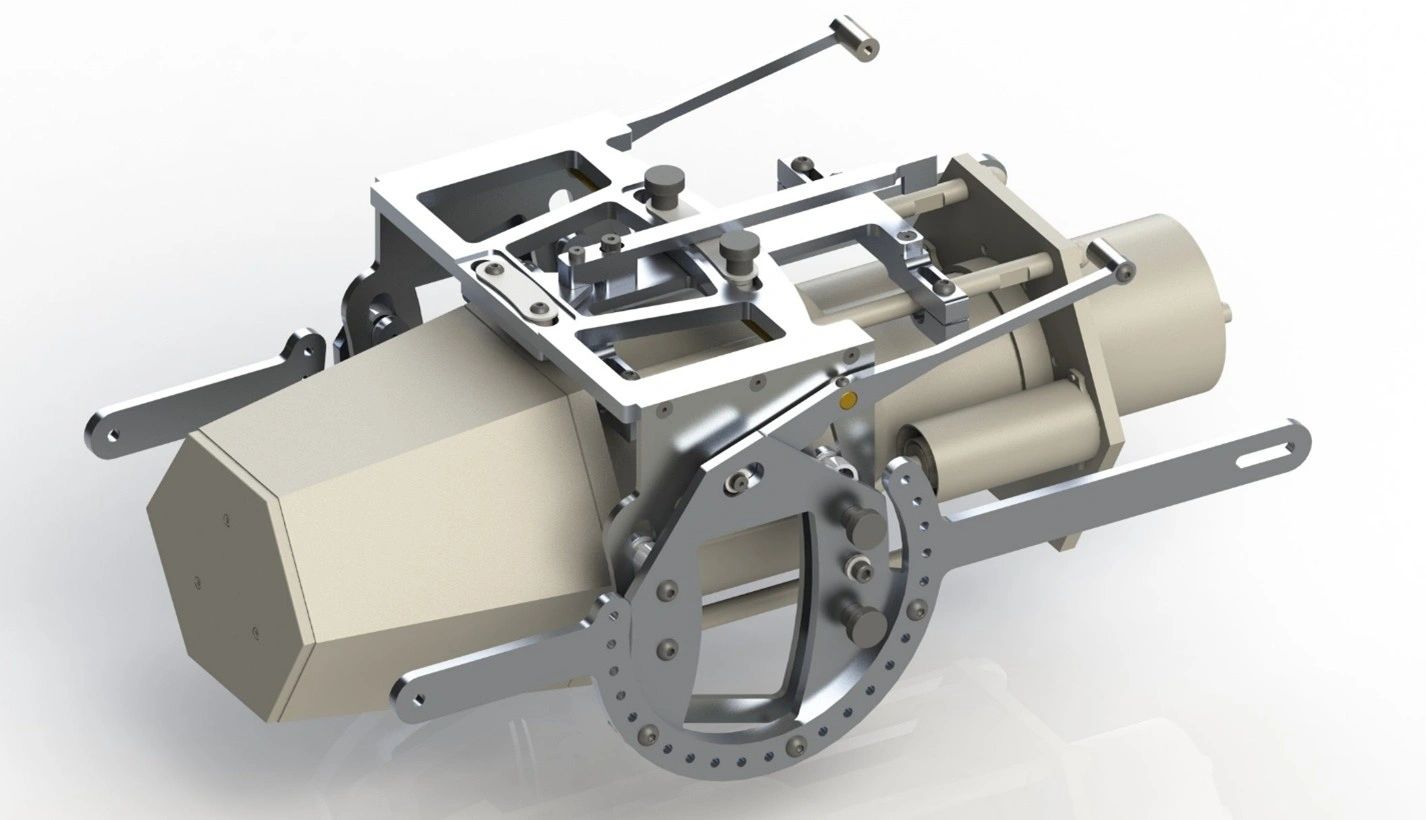

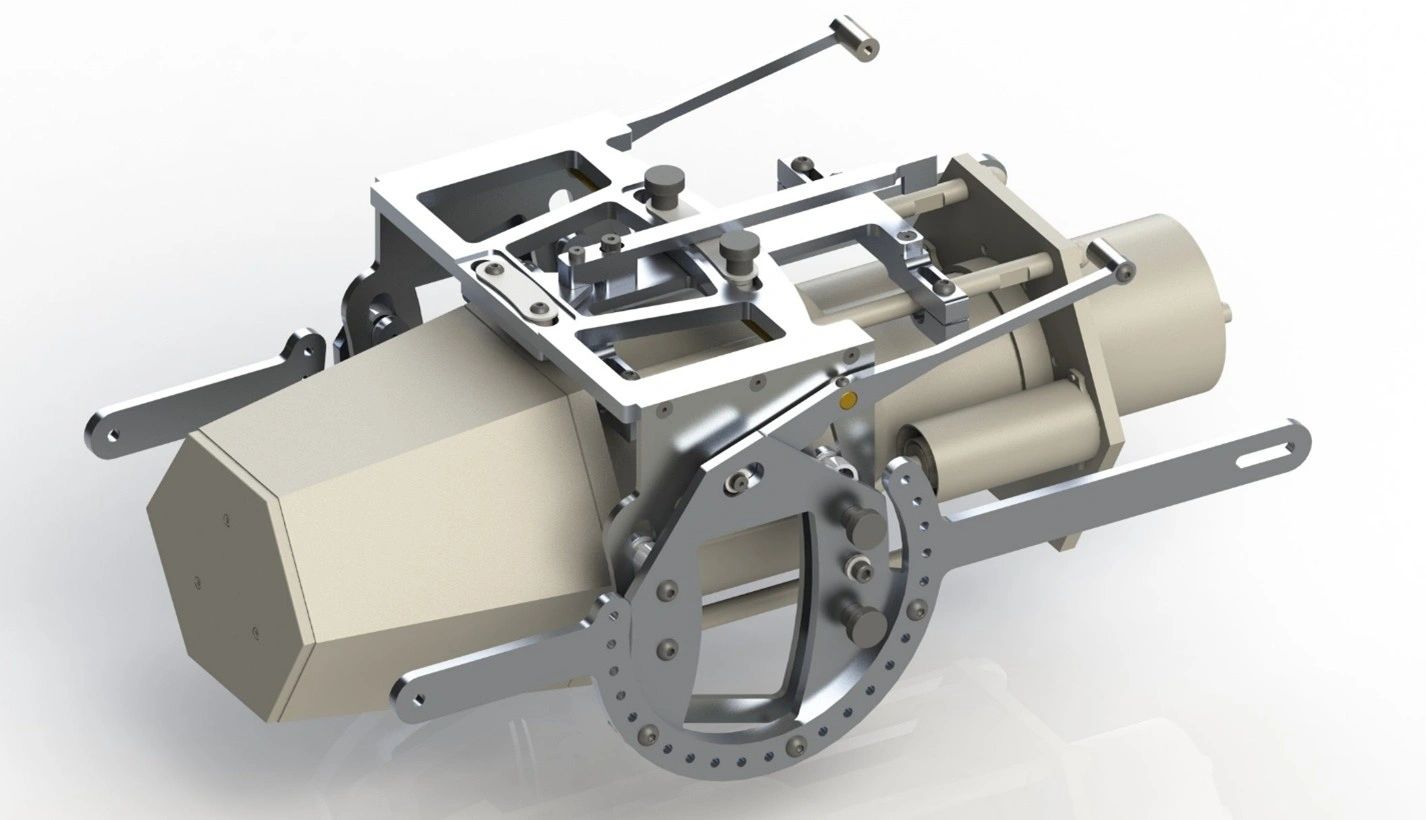

Sixty-five of these neutron detector mounts comprised a "detector wall" for a nuclear physics experiment. I solved several challenging design constraints, designed the entire device and CNC machined many parts.

This working 10X spyglass was manufactured by undergraduate students in a short course giving them a taste of machine shop life. I integrated design, materials, work holding and CNC programming into a seamless production system producing 72 copies every year.

This cutaway shows an assembly that accepts and holds custom sensors-on-a-chip measuring compositions of flowing gas. A lack of off-the-shelf components for this necessitated me to design a custom solution.

Still unsure how I feel about graduate students blowing up my parts. These discs and slugs made the ultimate sacrifice in the name of explosives research. While the geometry is simple, I worked closely with the researcher to provide parts that accommodate variations in slug diameters.

This microfluidic device passes particle-laden fluid between to cover glasses spaced about .001 inches apart. This allows microscopic imaging and manipulation of particles down to 1 micron in diameter.

Yeah. I design and build custom furniture too. This original coffee table, commissioned by Denver couple, was inspired by ancient Roman chair designs.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.